Applications for Dry Ice Blasting

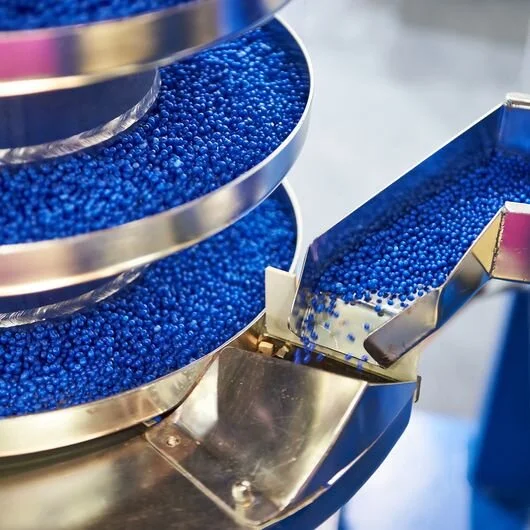

Plastic Injection Mold Cleaning

ICEsonic dry ice blasting is a fast, effective and non-abrasive way of cleaning. Due to the dry ice blasting technology, mold cleaning can be performed on an operational mold press at operating temperatures. It is used to clean extruder screws, dies and casts, ovens, mixers, molds and other plastic injection equipment. Dry ice blasting will improve operational efficiency, quality parts and reduce costs.

Food Processing and Packaging

The food industry has strict cleaning and disinfection programs to maintain hygiene standards. Risks of a poorly planned cleaning program include bacteria buildup from water blasting, salmonella from decaying food particles, quality issues, disposal costs, and liability. Dry ice is an approved medium by the EPA, USDA & FDA, and is non-toxic, non-hazardous and inhibits mold & bacteria growth. ICEsonic dry ice blasting is safe to use with food processing and packaging equipment, removes buildup like wax, glue, proteins, grease and other. Cleaning with dry ice does not release harmful gases into the atmosphere and does not generate secondary waste.

Automotive Industry

Dry ice blasting can be used for cleaning permanent core molds, such as: panel, seat, tire and gasket molds. ICEsonic dry ice blasting can be used on molds at operating temperatures. There is no need for cooling or removing of the mold. Due to the non-abrasive properties of dry ice, it eliminates wear on molds. ICEsonic dry ice blasting can also effectively cleans auto body welding lines and eliminates the need for manual cleaning and scraping.

Printing

Cleaning with dry ice offers the printing industry many advantages over traditional cleaning methods. Traditional methods are time consuming and labour intensive, so most printing facilities avoid regular cleaning. Ink builds up on frames, decks, and gears. Ink mist clogs vent slots and nozzles, in turn reducing air flow. Press speeds are then lowered, resulting in lost production and lower quality output. Ink trays used in the printing industry get easily cleaned with the help of CO2 blasting. Hard ink, dry or wet; all types of residues are removed without altering or tampering with the original shape of the trays. Whether it is glue pot, ink trays, ICEsonic dry ice blasting systems can clean various web presses like Flexography or web-fed; and are designed to help you clean hard to reach places.

Restoration and Remediation

ICEsonic dry ice blasting is successful in removing soot, odours and other residues caused by fire and smoke. This cleaning method is able to remove up to 100% of mold spores. Dry ice is an approved medium by the EPA, USDA & FDA, and is non-toxic, non-hazardous and inhibits mold & bacteria growth. Dry ice blasting is supported by the Institute for Inspection, Cleaning and Restoration Certification (IICRC) and Indoor Air Quality Association (IAQA) as a preferential removal media for mold remediation. It’s a chemically free process, does not create secondary waste and eliminates manual cleaning. Due to its non-abrasive properties this cleaning method is ideal for historical restoration (preservation) because it will not damage the surface. Dry ice blasting can be applied on a variety of materials such as brick, stone, metal, wood, clay, marble.

Textile Industry

Lint, glue and other residuals generate problems in the textile industry. ICEsonic dry ice blasting system is designed to remove a variety of buildups from textile production equipment. Dry ice blasting doesn’t create secondary waste or moisture enabling you to clean in-place without disassembling your equipment. Non-abrasive properties of the dry ice make dry ice blasting excellent for frequent use without causing damage on production equipment.

More Applications for Dry Ice Blasting

-

ICEsonic dry ice blasting system is a non-abrasive and non-conductive way of cleaning power generation equipment. This fast and environmentally safe way of cleaning allows you to clean in-place. Using this cleaning method there is little to no disassembly tasks and no need for cooling down the equipment. Dry ice blasting effectively removes grease, oil, dirt and carbon from your power generation equipment improving readings and machinery efficiency by 70%.

-

ICEsonic dry ice blasting provides economic and quick cleaning solution for permanent molds, core boxes, die casting tooling and additional equipment. Dry ice blasting reduces downtime through cleaning in place, without disassembly or cooling down. It is a non-abrasive and non-corrosive cleaning process that does not create secondary waste. Due to kinetic energy, dry ice spreads throughout the cracks eliminating waste which results in improved quality of the final product and prolonged lifespan of the machinery.

-

The accumulation of waste and mold release agents can cause imperfections and defects to the final product. With dry ice blasting it’s easier to hold tolerances on parts and decrease the amount of scrap. Dirty molds affect quality and productivity. Removing and reinstalling molds may cause tool wear. Dry ice cleaning eliminates the risk of mold and tool damage. With ICEsonic dry ice blasting system you can clean in-place while tire and rubber molding machines are operational.

This cleaning method reduces downtime production and eliminates cooldown requirements. Non-abrasive properties of dry ice ensure no damage to the molds. Dry ice blasting is a fast and efficient cleaning method that reduces cleaning time and labor costs. It does not require additional chemicals nor creates secondary waste which makes it environmentally safe.

-

ICEsonic dry ice blasting process is ideal for removing paint, decals, dirt, grease, oils from landing gear and the outer hull of aircraft. Also, it can remove rubber skid marks, burnt carbon deposits, engine exhausts, wheel wells, and adhesives from floor panels of aircraft.

ICEsonic dry ice cleaning can be used on and around bearings, machined surfaces, moving parts, painted surfaces, electrical equipment, glass, or any sensitive area.

-

Bitumen, tar and other buildup accumulate frequently preventing the mining equipment to operate properly. Dry ice blasting safely and efficiently removes residues from mining equipment. With the help of ICEsonic’s dry ice blasting system you will reduce production downtime, decrease risks of breakdowns and extend the operational life of your mining equipment. It doesn’t create secondary waste which results in reduced disposal costs and enables you to quickly and safely prepare for immediate painting and coating of your equipment.

ICEsonic’s dry ice blasting system offers a new green cleaning technology utilizing a dry ice blasting with addition of an abrasive to remove stubborn buildup which cannot be eliminated with dry ice only. The ICEsonic DRY ICE + abrasive module is simply attached to all standard ICEsonic dry ice blasters and offers perfect solution for NDT testing.

-

Dry ice blasting is a perfect solution for eliminating buildup from your oil and gas industry equipment because it is non-abrasive, non-flammable and non conductive. The process uses dry ice pellets at −79 °C and upon impact pellets freeze and detach the contaminants from the surface.

Due to kinetic explosion the pellets rapidly change from solid to gas (sublimation) leaving the surface dry and clean. Safely and without damage, ICEsonic dry ice blasters will remove bitumen, oil and other accumulation from heat exchangers, motors, pumps, vessels, pipelines and holding tanks.

-

Dry ice blasting is a completely dry process and ideal for the pharmaceutical industry. Water-based cleaning methods can cause bacteria growth and therefore health risks. Dry ice is an approved medium by the FDA, and is non-toxic, non-hazardous and inhibits mold & bacteria growth. Due to non-abrasive properties of dry ice, the process preserves molds and tooling which results in significant reduction of tooling replacement costs.

ICEsonic provides dry ice blasting machines for in-place cleaning. This cleaning method grants you faster and more effective cleaning that doesn’t create secondary waste.

-

The versatility and diversity of cleaning with dry ice enables you to clean from sensitive electrical components to thick grease and burnt carbon. With ICEsonic dry ice blasting you can clean in-place and eliminate manual cleaning. It’s an effective and non-conductive cleaning method which does not require chemicals.

Dry ice blasting allows you to clean equipment frequently which reduces risks of failures and service disruptions. This method prevents the interruption of unexpected service of generators, motors, cooling fans, railcars and other supporting equipment in public transportation.